PLATE CLARIFIER (Plate &Tube Settler)

PLATE CLARIFIER (Plate &Tube Settler)

Range of Clarifiers for pre-treatment of raw water. Clarification followed by filtration is required if water is drawn from a highly turbid water source such as River. Filtration, however is required for almost any source of surface water such as lakes, dam etc.

In Plate clarifiers we use a series of inclined plates. These inclined plates provide a large effective settling area for a small footprint. The inlet stream is stilled upon entry into the clarifier. Solid particles begin to settle on the plates and begin to accumulate in collection hoppers at the bottom of the clarifier unit. The sludge is drawn off at the bottom of these hoppers and the clarified liquid exits the unit at the top by weir.

Our Lamella or Plate for clarification of highly turbid waters

Applications:

Municipal

• Filtration Pretreatment • Backwash Water Treatment • Primary and Secondary Settling • Tertiary Treatment

Industrial

• Metal Hydroxide Wastewater • Industrial Process Water • Pressure/ Vacuum Filtrate Clarification • Specific Minerals Applications

PRODUCT RANGE: – Capacity 5 m3/h to 250 m3/h and above.

FILTER

Filtration is a process of physical  removal of suspended matter. Our Multi Grade filter comprises a MS pressure vessel containing media, provided externally with valves and piping to direct and control flow of water during treatment and cleaning. The media is supported by layers of crushed gravels and graded pebbles of specific size. Most of the suspended particles & most of the iron content in water is removed. The percolate is collected from the bottom of the Multi Grade filter through either the false bottom collecting nozzle covered with a blind flange or Header Lateral Or, Strainer mounting on strainer plate. We also manufacture & supply of Iron Removal Filter, Pressure Sand Filter, Dual Media Filter, Side Stream Filter, Activated Carbon Filter in several application of water treatment.

removal of suspended matter. Our Multi Grade filter comprises a MS pressure vessel containing media, provided externally with valves and piping to direct and control flow of water during treatment and cleaning. The media is supported by layers of crushed gravels and graded pebbles of specific size. Most of the suspended particles & most of the iron content in water is removed. The percolate is collected from the bottom of the Multi Grade filter through either the false bottom collecting nozzle covered with a blind flange or Header Lateral Or, Strainer mounting on strainer plate. We also manufacture & supply of Iron Removal Filter, Pressure Sand Filter, Dual Media Filter, Side Stream Filter, Activated Carbon Filter in several application of water treatment.

PRODUCT RANGE :-Capacity 5 m3/h to 350 m3/h and above.

We also supply FRP in construction for small capacity of plant as per client’s requirement.

SOFTENER

SOFTENER

Softening is a reversible ion exchange process where in the hardness forming ions are exchanged with Na+ ions present in the resin group. SMFE offers a wide range of Softening plants with versatility in flow, flexibility in resin quantities & easy in operation Softeners are available in MS (painted), MSRL, FRP construction.

Softening is a widely used technology for reducing hardness forming irons (Ca++ & Mg++) which precipitate & scale also at very low temperatures & pressures.

We also supply FRP in construction for small capacity of plant as per client’s requirement

PRODUCT RANGE: – SMFE offer wide range of Softeners from 0.5 m3/hr to 100 m3/hr and above.

DEMENERALISER PLANT (DM)

Ion Exchange Resin based treatment for reducing the Total Dissolved Solids to desired levels as befitting different end – users. This could involve a single sequence Strong Acid Cation and Strong Base Anion Exchange or a repeated exchange involving a Weak Acid Cation, a Strong Acid Cation, a Weak Base Anion and a Strong Base Anion Exchange Resin. Either of these may be followed by a final polishing Mixed Bed Exchanger. Combination techniques such as split stream dealkalisation using Softener and Weak acid Cation Exchange etc. for partial reduction in Total Dissolved Solids. DM water finds wide application in the field of stream, power, process & cooling.

Ion Exchange Resin based treatment for reducing the Total Dissolved Solids to desired levels as befitting different end – users. This could involve a single sequence Strong Acid Cation and Strong Base Anion Exchange or a repeated exchange involving a Weak Acid Cation, a Strong Acid Cation, a Weak Base Anion and a Strong Base Anion Exchange Resin. Either of these may be followed by a final polishing Mixed Bed Exchanger. Combination techniques such as split stream dealkalisation using Softener and Weak acid Cation Exchange etc. for partial reduction in Total Dissolved Solids. DM water finds wide application in the field of stream, power, process & cooling.

All Cations like Ca, Mg, Na are exchanged with H+ ions present in the resin group of the first bed called Cation Unit. Similarly all Anions like Cl, SO4, NO3 are exchanged with OH- ions present in the resin group of the second bed called Anion unit. Degasser Tower is a part of DM unit which is used where presence of alkalinity is high.

PRODUCT RANGE: – SMFE offer wide range of DM Plant from

0.5 m3/hr to150 m3/hr

Reverse Osmosis Plant (RO)

This Membrane based systems are most widely used technology in now a days for reducing TDS in the raw water. Require minimum maintenance and operator Attention. Although capital intensive, has very low operating expenses as compared to Demineralisers above 700-800 ppm TDS load of raw water. SMFE have a wide experienced in design the software system (Hydranautics and Dow membranes with different sizes. like-8040 & 4040 types) and capacities of the membrane technology of various RO plants for various source water.

This Membrane based systems are most widely used technology in now a days for reducing TDS in the raw water. Require minimum maintenance and operator Attention. Although capital intensive, has very low operating expenses as compared to Demineralisers above 700-800 ppm TDS load of raw water. SMFE have a wide experienced in design the software system (Hydranautics and Dow membranes with different sizes. like-8040 & 4040 types) and capacities of the membrane technology of various RO plants for various source water.

SMFE offers separate control panel both dry & wet panel is mounted on a single skid for operator friendly. SMFE design the system in such a way that all the monitoring unit will be mounted on the skid. PLCM based auto monitoring plant will be offered by SMFE.

PRODUCT RANGE: – SMFE offer wide range of RO Plant along with accessories from 200 Lts/Hr. to 120.0 M3/Hr.

ULTRA FILTRATION (UF)

UF is a membrane Based technology and generally used to remove colloidal Silica and related colloid Iron, Aluminum and Magnesium in water causing fouling, scaling and performance of the plant. UF is a low-pressure cross-flow technique that separates particles and the molecular level (0.01 microns).

UF is a membrane Based technology and generally used to remove colloidal Silica and related colloid Iron, Aluminum and Magnesium in water causing fouling, scaling and performance of the plant. UF is a low-pressure cross-flow technique that separates particles and the molecular level (0.01 microns).

USING AREAS: –

Chemical and pharmaceutical manufacturing, food and beverage processing, and waste water treatment, employ ultra filtration in order to recycle flow or add value to later products. But also blood dialysis belongs to ultra filtration.

1) Drinking Water: – UF can be used for the removal of particulates and macromolecules from raw water to produce potable water. UF is used for pre filtration in reverse osmosis plants to protect the RO.

2) Protein Concentration: – UF is used extensively in the dairy industry; particularly in the processing of cheese whey to obtain whey protein concentrate (WPC) and lactose-rich permeate.

3) Other Applications: – a) Filtration of effluent from paper pulp mill

b) Process and waste water treatment c) Fruit juice concentration and

d) Clarification Laboratory grade manufacturing, etc

Ultra Violet Ray (UV) : –

Ultraviolet (UV) sanitizing units are used in many water purification systems to control bacteria and have certain applications in animal drinking water systems. Ultraviolet or UV energy is found in the electromagnetic spectrum between visible light and x-rays and can best be described as invisible radiation. UV disinfection does not remove dissolved organics, inorganics or particles in the water. UV disinfection is most effective for treating high-clarity purified reverse osmosis or distilled water purified reverse osmosis or distilled water.

UV units for water treatment : –

Special low-pressure mercury vapor lamps produce ultraviolet radiation at 254 nm, the optimal Wave length for disinfection and ozone destruction. The UV lamp never contacts the water; it is either housed in a quartz glass sleeve inside the water chamber or mounted external to the water which flows through UV transparent Teflon tubes. Some ultrapure water systems use 185 nm UV units for reducing TOC (total organic carbon).

ABOUT WASTE WATER TREATMENT PLANT & USING PURPOSE

SM Fluid Engineering Private Limited provide sustainable Effluent treatment plant Solutions based on following:

- ETP applicable to small, medium to large scale applications (typical- 50-400 M3/day)

- ETP with Anaerobic and MBBR based systems.

- ETP with MBR based systems having very high BOD load and space constrains.

- ETP with DAF based systems followed by Anaerobic/ Aerobic Digestion process.

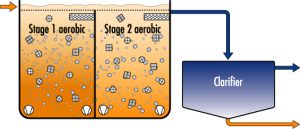

MBBR System

Packaged ETP applicable to small systems (Typical 10-100 M3/Day)

- Package ETP with aerobic and anaerobic treatment

- Package ETP with UASB reactor

- Packager ETP with MBBR based systems.

- Package ETP with FAB based systems.

- Package ETP with MBR based systems for very high BOD load.

Sewage Treatment Plant

SM Fluid Engineering Private Limited provide sustainable Sewage treatment plant Solutions based on following:

Zero Waste being discharge-on need basis Saving Ground water resources, Eco friendly Systems to achieve a clean and green environment for protection of public/community health.

PRODUCT RANGES OF STP: –

Capacity 10 M3/D to 400 M3/D and above. Likes: –

a) Packaged STP

b) RBC Based STP

c) STP Submerged –Packaged

d) Prefabricated STP

e) MBBR Based STP

f) Extended Aeration Based STP

g) FAB Based STP

h) UASBR Based STP.